Tapered Roller Bearing Housed Units

Installation and Lubrication Instructions

INSTILLATION

-

Ensure that the shaft is clean, free from nicks and burrs, straight and of proper diameter. See

Table 1 for recommended shaft tolerances. The bearing should not be mounted on

a worn section of the shaft. Use of shafts with hardness greater than Rc 45 will reduce the effectiveness

of locking devices.

-

Slide the unit into position on the shaft.

-

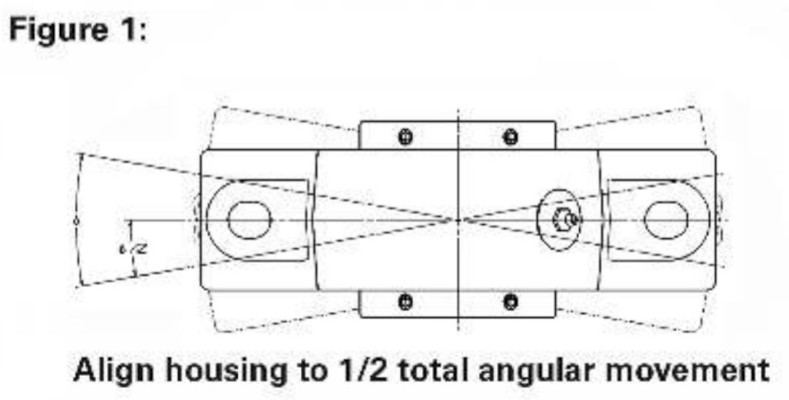

Install housing attachment bolts. Check housing alignment (Figure

1). Verify mounting surfaces are in the same flat plane to help make

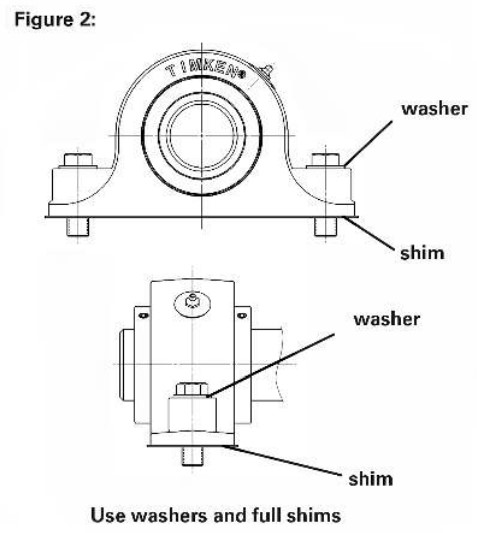

sure good alignment is achieved. If shimming is required to minimize

misalignment, use full shims across entire housing base (Figure 2). The

bolts then need to be alternately torqued securely to their mounting

supports. Flat washers should be used when installing any kind of

housed unit (Figure2). Washers should be properly sized to bolt diameter

and should not be an SAE grade, which is smaller.

-

Ensure that the bearing insert can still be rotated.

-

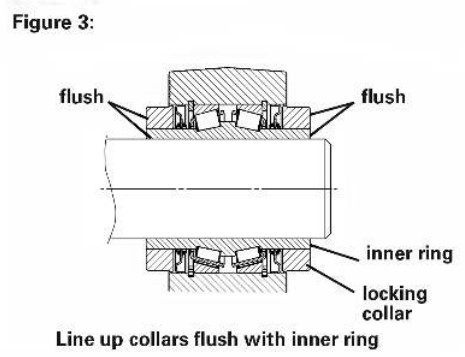

Line up locking collars flush with the end of the cone (inner ring) face

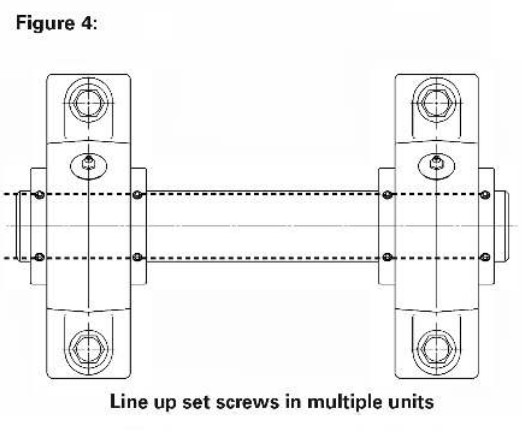

(Figure 3). Tighten set screws alternately as per Table 2. Set screws in

multiple units should be aligned to each other (Figure 4).

LUBRICATION

-

This information is to aid in the proper lubrication of Timken tapered

roller bearing housed units for the majority of applications.

-

Bearings have been factory prelubricated with Timken® Premium All

Purpose Industrial Grease which is an NLGI No. 2 lithium complex based

grease. This is suitable for normal operating conditions. Units should be

relubricated with the Timken grease or one that is compatible and made

for roller bearings. It is vital that the greases used are compatible. Please

consult with a Timken representative for the grease specifications if

the use of a grease other than the Timken grease mentioned above is

needed.

-

Normal service is considered as operation in a clean, dry environment

at temperatures between -34º C to +82º C (-30º F and +180º F). If service

is beyond normal conditions due to speed, temperature, or exposure

to moisture, dirt or corrosive chemicals, periodic relubrication may

be advisable. For extreme conditions or conditions in which special

chemicals are used, a Timken representative should be consulted.

- After extended storage or periods when the unit is not in operation, fresh grease should be added.

-

For units operating in dirty or wet environments, the bearing should

contain as much grease as possible, based on the shaft speed, to help

protect against contamination. For slower applications, with shaft

speeds typically less than 200 rpm, the unit should have grease added at

start-up to fill the bearing.

-

Lubrication affects the bearing operating temperature as well. If the bearing

does not have enough grease, this could lead to higher temperature

operation due to inadequate lubrication film thickness. Excessive grease

will lead to higher operating temperatures due to grease churning. This can

cause bearing overheating. To avoid this, it may be necessary to remove

some of the grease inside the unit. The grease fitting may be removed briefly

in this circumstance to allow excess grease to purge (the grease fitting must

be replaced). It is best to observe the bearing and its temperature and adjust

the lubrication as needed.

RELUBRICATION

-

Adequate lubrication is an essential element to the bearing life.

Table 3, shown on reverse side, can be used as a suggested initial point of

reference. Relubrication frequency and quantity intervals are best developed

through experience for each application, based on types of service, which

may differ from the suggestions in the table.

-

When the bearing is not in operation for an extended period of time, grease

should be added to prevent corrosion.

-

The recommended shaft tolerances shown in Table 1 are for normal loaded

applications. Please refer to the engineering section in the Timken Tapered

Roller Bearing Housed Unit catalog to verify the maximum allowable slip fit

radial load and to determine if a tighter fit is required. Table 3 shows general

lubrication suggested starting points only. Please read the entire installation

instructions prior to using these tables. Applications should be regularly

reviewed and lubrication amounts and intervals modified as needed to

assure best results.

| Recommended Shaft Tolerances | |

|---|---|

| Shaft Size | Tolerances |

| Up to 1-1⁄2" 35 mm |

+0.0000” to -0.0005” +.000 mm to -.013 mm |

| 1-5⁄8" 40 mm to 100 mm |

+0.0000” to -0.0010” +.000 mm to -.025 mm |

| 4 7⁄16" to 5" 110 mm to 125 mm |

+0.0000” to -0.0015” +.000 mm to -.038 mm |

| Recommended Set Screw Tightening Torque | ||

|---|---|---|

| Shaft Size | Set Screw Size | Tightening Torque (in.-lbs) |

| 1-3⁄16" to 1- 35 mm to 40 mm |

5⁄16 - 18 | 155 |

| 1-3⁄4" to 2-1⁄2" 45 mm to 65 mm |

3⁄8 - 16 | 275 |

| 2-11⁄16" to 3-1⁄2" 70 mm to 90 mm |

1⁄2 - 13 | 615 |

| 3-15⁄16" to 5" 100 mm to 125 mm |

5⁄8 - 11 | 1315 |

| Suggested Relubrication Intervals (Based on 8 Hours/Day Operation) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Environment | Clean: Un-Exposed | Moderate: Exposed | Extreme: Harsh | ||||||

| **Application Speed |

Low | Med | Hi | Low | Med | Hi | Low | Med | Hi |

| Greasing Interval |

1 year |

2 months |

2 weeks |

1 month |

2 weeks |

* | 1 week |

1 week |

* |

*Use extra caution due to heat generation.

**(Low < 25% max rpm; 25%<Med<75%; 75% < Hi) - See Table 4 for max rpm values.

Relubriciation frequency and quantity are best developed through experience. And at

all times, follow Original Equipment Manufacturer’s maintenance instructions.

| Max RPM of Bearing |

4490 | 3820 | 3320 | 3050 | 2730 | 2420 | 2060 | 1640 | 1530 | 1360 | 1200 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Shaft Size |

1-3⁄16" to 1-1⁄4" |

1-3⁄8" to 1-7⁄16" 35mm |

1-3⁄2" to 1-11⁄16" 40mm |

1-3⁄4" to 2" 45 mm to 50mm |

2-3⁄16" to 55 mm |

2-1⁄4" to 2-1⁄2" 60mm to 65mm |

2-11⁄16" to 3" 70mm to 75mm |

3-3⁄16" to 3-1⁄2" 80mm to 90mm |

3-15⁄16" to 4" 100mm |

4-7⁄16" to 4-1⁄2" 110mm to 115mm |

4-15⁄16" to 5" 125mm |

Failure to observe the following warnings

could create a risk of death or serious injury

Proper maintenance and handling practices are critical.

Always follow installation instructions and maintain proper lubrication.

Overheated bearings can ignite explosive atmospheres.

Special care must be taken to properly select, install, maintain, and lubricate

housed unit bearings that are used in or near atmospheres that may contain

explosive levels of combustible gases or accumulations of dust such from

grain, coal, or other combustible materials. Consult your equipment designer or

supplier for installation and maintenance instructions.

If hammer and bar are used for installation or removal of a part, use a mild steel

bar (e.g., 1010 or 1020 grade). Mild steel bars are less likely to cause release of

high-speed fragments from the hammer, bar or the part being removed.

Failure to follow these cautions

may result in property damage.

NOTE

Do not use excessive force when mounting or dismounting the unit.

Follow all tolerance, fit, and torque recommendations.

Always follow the Original Equipment Manufacturer’s installation

and maintenance guidelines.

Ensure proper alignment.

Never weld housed units.

Do not heat components with an open flame.

Do not operate at bearing temperatures above 250˚ F (121˚ C).